The ATI520J Portable Cable Terminal Swager is a lightweight, pneumatically powered tool engineered for precision swaging of MS sleeve‑type and ball‑end cable terminals in aerospace, defense, and industrial environments. It accommodates cable sizes from 1/16" (0.0625 in) up to 3/16" (0.1875 in)

Swaging is performed using matched die sets inserted into the yoke cavity. The operator applies regulated air pressure (minimum 90 psi, via a ≥3/8" I.D. airline) while rotating the cable or terminal during swaging to ensure uniform metal deformation and optimal terminal seating.

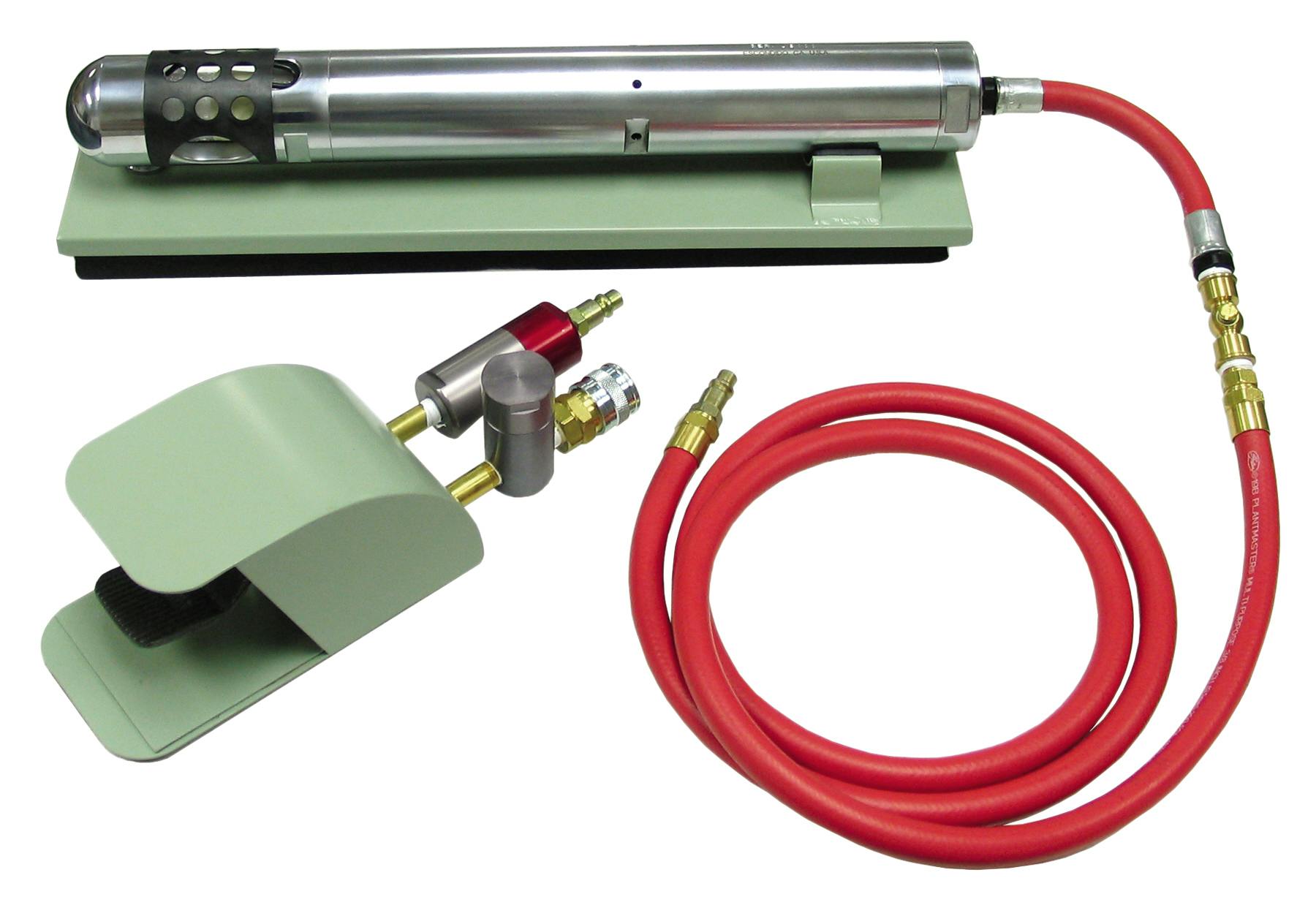

Included Components:

Base plate for stable bench mounting (optional hand‑held operation also supported)

Air hose and foot control for pneumatic operation

Swaging Dies Supported:

Double‑shank ball‑end terminals: ATI520CDB‑2 through ATI520CDB‑6 for 1/16" to 3/16" cables

Single‑shank ball‑end terminals: ATI520CSB‑2 through ATI520CSB‑6

Plain ball‑end terminals: ATI520CB‑2 to ATI520CB‑4

MS sleeve‑type terminals: ATI520CS‑2 through ATI520CS‑8 covering 1/16" to 1/4" cable sizes

Cable cut‑off and trim dies: ATI520CD‑2 through ATI520CD‑8, with corresponding punches ATI520CP‑2 through ATI520CP‑8 Operational Highlights:

Pneumatic drive ensures consistent force for swaging cycles.

Rotational swaging technique (180° arcs or full revolutions) yields quality swage profiles while minimizing tooling wear. Oiler for maintenance: Built‑in tool oiler should be refilled every eight hours with air‑tool lubricant

Applications:

Ideal for aerospace, aviation maintenance, defense, and industrial settings where precision cable-terminal swaging is critical.

Condition & Warranty Used Tools:

This swager is offered as a used, fully serviced unit, verified for operational performance to manufacturer specifications. Cosmetic wear may be present, but all functional parts meet strict quality standards. A 90-day warranty covers defects in materials and workmanship under normal use; damage from misuse, improper operation, or cosmetic wear is excluded.