When it comes to aerospace-grade tube fitting installations, understanding the difference between radial swaging and axial swaging is crucial. Each method applies a different force and has different use cases in hydraulic and pneumatic systems.

What Is Radial Swaging?

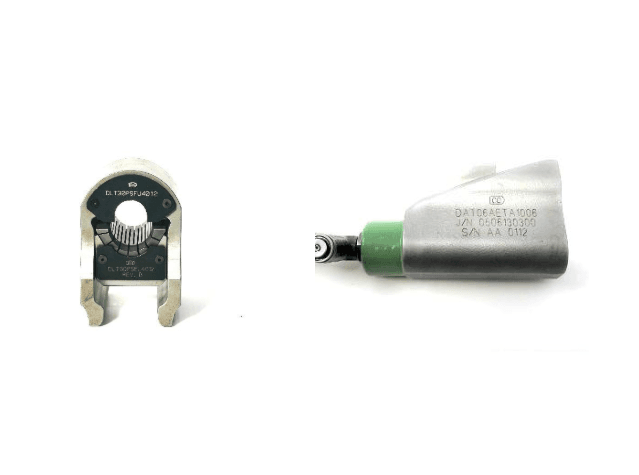

Radial swaging is the most commonly used technique in Permaswage tooling systems. It compresses a fitting uniformly 360 degrees around the tubing using opposing die halves. This method is ideal for:

- Permanent, high-pressure hydraulic connections

- Applications requiring vibration resistance

- Lightweight systems with minimal space

Advantages:

- Strong, uniform seal

- Compatible with soft metal tubing (e.g., 304/321 stainless, titanium)

- Easy to inspect and verify with go/no-go gauges

What Is Axial Swaging?

Axial swaging involves driving a collar or sleeve axially (lengthwise) over a fitting or ferrule, causing it to compress onto the tube. While less common in aerospace, it is used in:

- Larger diameter pipe systems

- Certain commercial or industrial applications

- High-vibration, non-critical installations

Advantages:

- Simpler tooling in some setups

- May require less operator training

- Useful for systems where radial access is limited

Key Differences

| Feature | Radial Swage | Axial Swage |

|---|---|---|

| Compression Method | Around tube circumference (360°) | Along tube axis |

| Strength & Sealing | Higher precision & pressure rating | Moderate pressure use cases |

| Tool Type | Permaswage DLT kits (e.g., 3001) | Axial collar-drive swage tools |

| Use in Aerospace | Common and certified | Rare or niche |

Why Permaswage Uses Radial

Permaswage tooling systems are engineered for the precision and durability required in aviation. The radial method provides consistent sealing performance, critical for maintaining hydraulic integrity under extreme temperatures and pressures.

Final Thoughts

Choosing the right swaging method impacts the performance and safety of your hydraulic systems. For most aerospace applications, radial swaging remains the gold standard — and it’s the foundation of every Permaswage tool we sell. Want to know if your system should use radial swage? Contact Top Flight Tools — we’ll help you match the right technique to your platform.

⚠️ Disclaimer Top Flight Tools (TFT) is an independent reseller and is not affiliated with, sponsored by, or endorsed by Permaswage® or Precision Castparts Corp. (PCC). All product names, trademarks, and registered trademarks are property of their respective owners. Any reference to Permaswage® products, specifications, or part numbers is for informational purposes only. All Permaswage® trademarks and part numbers remain the property of their respective companies. TFT assumes no responsibility for misuse of this information or misrepresentation of affiliation.